60 years of worldwide experience

Liebherr-Mischtechnik GmbH is one of more than 130 companies of the international Liebherr group.

The product portfolio of measuring systems has been developed from the experience in mixing technology.

To guarantee a constant high quality and best results of produced concrete a reliable moisture measurement is most essential. This well-engineered and innovative system is used worldwide for a wide range of materials today.

Sensor production

Since 1985 Liebherr develops, produces and distributes efficient moisture measurement systems for the industrial automation around the world.

At the Liebherr factory in Bad Schussenried the sensors are produced and calibrated in a ESD-protected production line.

Each sensor will be tested separately in a several hour process across the entire working temperature range before leaving the factory.

Development

Sensor development at Liebherr includes the total R&D value chain from the physical idea to the final solution, from the first concept to the finished product.

The competent electronic development and the experience from the field of construction machines under extreme conditions guarantee a very high reliability and a long life time of the sensors.

System overview

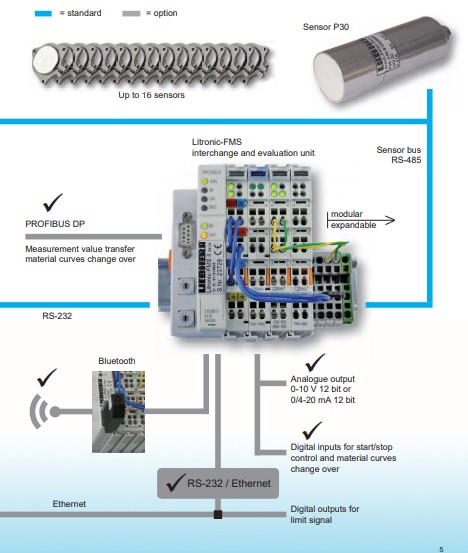

An autonomous stand-alone-system with almost unlimited possibilities. Highest quality and best results during process are guaranteed by the exact material moisture measurement.

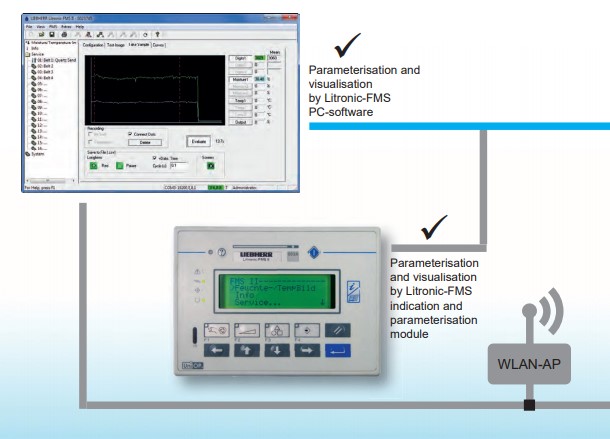

The Litronic-FMS will meet your requirements in any case. An easy-to-use PC software enables a fast and exact calibration.

Features:

1. Modular expandable construction

2. Fully reproducible sensors

3. Adjustable measuring range

4. Material curves change over

5. Material temperature compensation

6. Suitable for high material flow

7. Interference-free digital signal transmission

8. Installation of electronic components on DIN mounting rail (TS-35)

9. Suitable for batch and continuous processes

Application examples

Sensor installed in material chute under silo outlet

In the paper and cardboard industry

For sand and other aggregates

With DN 80 flange for diesel, oil and other emulsions

In sliding shoe for cullet (recycling glass)

Food compliant execution e.g. for margarine

Sensor P30 for small and space limited plants, e.g. for powder and fine aggregates

Fleece-, film- and felt webs

For wooden chips, sawdust, etc.

View in a bulk funnel with installed sensor.

Materials

Sand, quartz sand

Recycling glass, soda

Incineration and flue ash

Ore, minerals

Dust, slag

Different aggregates

Faundry sand

Raw materials, filter cake

Ceramic powder

Coal, coke, charcoal

Gypsum, talc

Lime, loam, clay

Mineral-, aluminium granules

Fertilizer

Installation places

Silo outlets, material chutes, buffle plates, conveyor belts, transfer points, dryers, screw conveyor, pipes, tanks,...

Options and accessories

Stainless steel housing for electronic module

Sensor with dust Ex-protection, zone 22

Funnel for fast moisture measurements in laboratories